Introduction:

In the realm of additive manufacturing, 3D printing has emerged as a transformative technology, revolutionizing the way products are conceptualized and produced. At the heart of this innovation are 3D printing material companies, essential players that develop and supply the diverse range of materials required for additive manufacturing processes. This article delves into the pivotal role of these companies, their impact on various industries, and the dynamic landscape of materials driving the evolution of 3D printing.

Diverse Material Portfolio:

3D printing material companies are instrumental in expanding the possibilities of additive manufacturing by offering a wide array of materials suited for different applications. These materials include plastics, metals, ceramics, resins, and even biomaterials. Each material has unique properties that cater to specific industry needs, enabling the production of prototypes, functional parts, and intricate designs with unprecedented precision.

Plastics and Polymers:

Among the most widely used materials in 3D printing are various plastics and polymers. PLA (polylactic acid), ABS (acrylonitrile butadiene styrene), and PETG (polyethylene terephthalate glycol) are popular choices for their affordability, versatility, and ease of use. These materials find applications in prototyping, product development, and the creation of consumer goods due to their favorable balance of strength and flexibility.

Metals for Industrial Applications:

3D printing material companies have made significant strides in developing metal alloys suitable for additive manufacturing. Materials like titanium, aluminum, and stainless steel are now utilized in industries such as aerospace, automotive, and healthcare. Metal 3D printing enables the production of complex and lightweight structures, contributing to advancements in engineering and design.

Resins for High Precision:

Resin-based 3D printing technologies, such as stereolithography (SLA) and digital light processing (DLP), rely on liquid photopolymers that solidify when exposed to light. These resins offer high precision and surface finish, making them ideal for applications in jewelry, dental prosthetics, and intricate prototypes. 3D printing material companies continue to innovate with resins, expanding the range of available colors, transparency levels, and material properties.

Biomaterials and Healthcare:

The healthcare industry has witnessed a profound impact from 3D printing material companies. Biocompatible materials and biomaterials are now used to create patient-specific implants, prosthetics, and even living tissues. This revolutionary intersection of 3D printing and healthcare has the potential to transform the way medical devices are produced and personalized for individual patients.

Innovations in Composite Materials:

3D printing material companies are driving innovations in composite materials, combining different elements to enhance the properties of printed objects. Carbon fiber-reinforced polymers, for example, provide increased strength and stiffness, making them suitable for applications in the automotive and aerospace industries. These composite materials open new avenues for lightweight and durable components.

Environmental Considerations:

As sustainability becomes a paramount concern, 3D printing material companies are actively exploring eco-friendly options. Bio-based polymers derived from renewable sources, recycled plastics, and materials with reduced environmental impact are gaining traction. The pursuit of sustainable 3D printing materials reflects the industry's commitment to minimizing its ecological footprint.

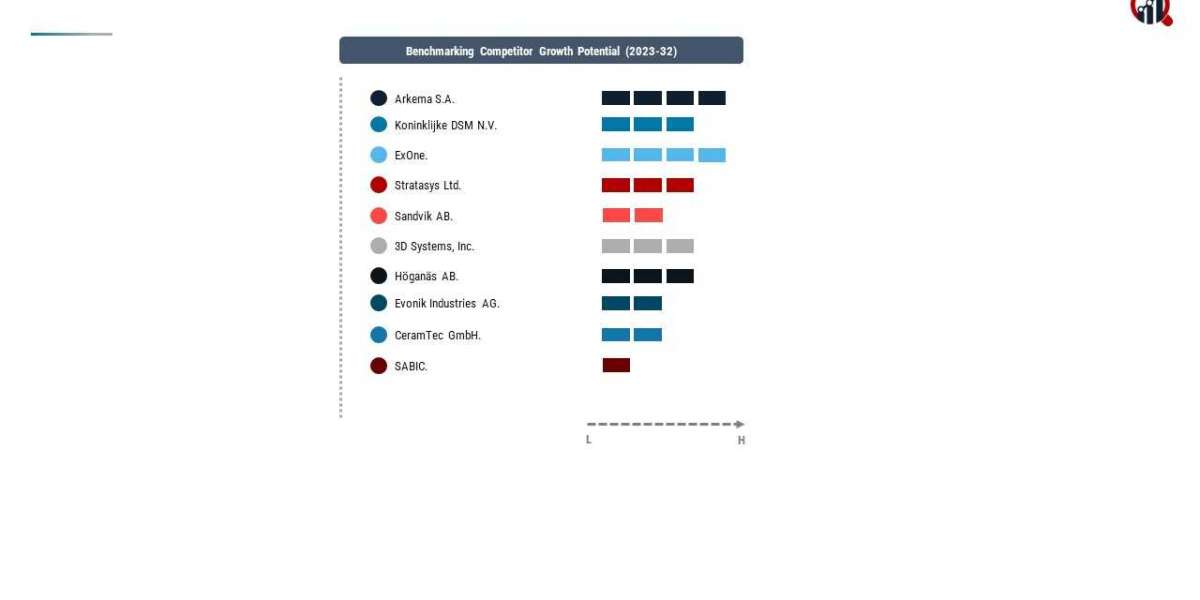

Challenges and Future Outlook:

While 3D printing has made significant strides, challenges such as material compatibility, cost, and scalability persist. 3D printing material companies continue to address these challenges by developing materials that meet industry standards, optimizing production processes, and collaborating with end-users to understand evolving needs. The future of 3D printing materials holds exciting possibilities, including the integration of smart materials, further advancements in bioprinting, and increased material recycling capabilities.

Conclusion:

3D printing material companies are catalysts for the ongoing revolution in additive manufacturing. Their commitment to innovation, diverse material portfolios, and responsiveness to industry demands are driving the evolution of 3D printing across various sectors. As these companies continue to push the boundaries of what is possible with 3D printing materials, we can anticipate further breakthroughs that will shape the future of manufacturing and product development.

Read more about this company page 3D printing material companies